| Cutting

Accurate Half-Blind Dovetails |

|

Many drawers

are held together with half-blind dovetail joints. One quick,

accurate way to cut this type of joint is with a router, a 1/2"

dovetail bit, a guide bushing, and a special dovetail jig.

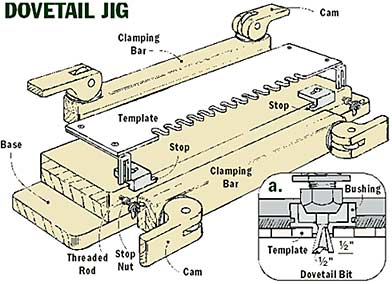

The half-blind dovetail jig is a comb-shaped template that fits

on a base, see the illustration below. The base has clamping

bars to hold the workpieces in place while the router is guided

in and out of the “fingers” on the template to cut

evenly spaced dovetails on a drawer’s front, back and

sides. |

|

| To cut dovetail joints with

a router and template requires a little planning ahead. For

example, the drawer for the chest is exactly 4 3/8" wide.

I planned for this width so the opening would accommodate a

drawer joined with router-cut dovetails. That is, the width

(height) of the drawer front has to be a multiple of 7/8".

This produces a dovetail joint that’s symmetrical both

on the top and bottom edges, see the photo right. |

|

|

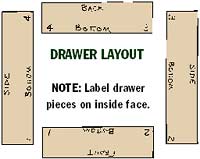

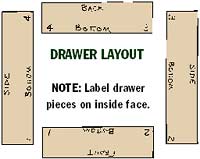

Another consideration

is the length of the drawer pieces. To make sure the corners

are square, check that the drawer front and back, as well as

the drawer sides, are equal lengths. Once the pieces are cut

to size, lay them out and label the bottom edge of each piece,

as shown left. Also, number the matching corners. |

|

Set

up

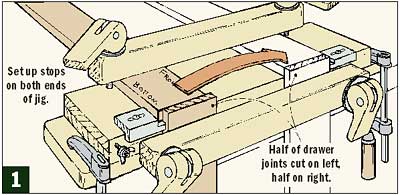

Setting up the jig takes some trial and error, so I first used

some scrap pieces that are the same thickness and width as the

drawer pieces. Then I made test cuts, before going on to the

real thing. Start by mounting a drawer side under the front

pressure bar and a drawer front under the top bar. Note: The

bottom edges should be tight against the left-hand stop block,

and the insides of the drawer should face out (Fig. 1). After

the drawer front is clamped down, reposition the drawer side

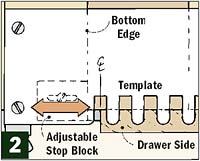

so the end is level with the drawer front. Next, mount the “comb”

template on the jig. The goal is to have the first notch of

the template centered on the bottom edge of the drawer side.

If it’s not, change the position of the stop block side

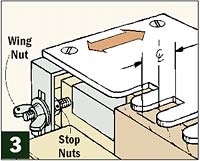

to side to adjust it (Fig. 2). Now hold the template flat on

the drawer front and tighten the wing nuts (Fig. 3). The location

of the stop nuts on the studs may take some minor adjustment. |

|

|

|

|

Router

Set-up

The router is guided in and out of the template with the aid

of a guide bushing (Detail a, of Dovetail Jig illustration above).

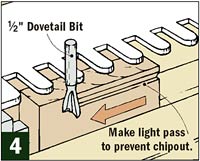

Next, mount a 1/2" dovetail bit in the router, making sure

the bit is centered in the guide bushing. If it’s not,

adjust the router’s base slightly. As for the depth of

the bit, start with it 1/2" deep (from the base), but you

may need to adjust the height of the bit.

Routing the Pieces

Now all of the drawer pieces can be

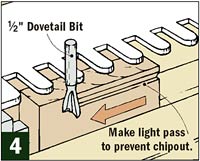

routed. To prevent chipout on the drawer sides, start by making

a light scoring pass, routing from right to left (Fig. 4). Then

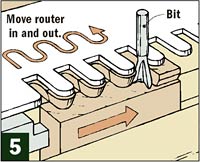

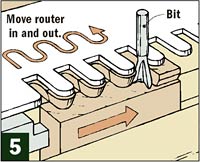

gently move the router in and out of the fingers, this time

moving the router from left to right (Fig. 5). You should be

able to feel the guide bushing stop at the back of each notch.

After routing, but before removing the pieces from the jig,

check that you’ve routed each socket evenly and all the

waste is removed. Take a look at the Drawer Layout drawing on

page 1. You’ve now routed the joint at the left front

corner of the drawer (marked No. 1). Next, rout the right rear

corner joint (marked No. 3). Mount the drawer side on the front

of the jig, the drawer back on the top of the jig — with

the bottom edges against the stop on the left and the insides

facing out. The other two joints (No. 2 and 4) are routed with

the pieces tight against the stop block on the right side of

the jig. Again, always clamp the drawer side to the front of

the jig, the inside of the pieces facing out, and the bottom

edges against the stops (this time on the right).When routing

the right side, follow the same procedure as you did on the

left. |

|

|

| To prevent

chipout on drawer side, start by making a light pass from

right to left. This creates a clean shoulder line. |

|

|

| Now move

router left to right, working in and out of notches. Bushing

must contact back of notch for complete cut. |

|

|

|

| Troubleshooting

Your Dovetails |

| Setting

up to make router-cut dovetails is always a trial-and-error

effort. You may need to fiddle around and readjust

trial pieces to get a perfect fit. See below for

pointers on how to fix possible problems. Most other

problems are usually caused by the pieces not being

clamped down in the jig so they’re flush across

the top, or because they move out of position as

they’re being routed. |

|

|

| TOO

LOOSE: If joint is too loose, increase

bit depth. TOO TIGHT: If joint is too

tight, decrease depth. |

|

|

| TOO

DEEP: If pins go deep, move template

toward you. TOO SHALLOW: If not deep

enough, move toward jig. |

|

|

| OFFSET:

If pieces don’t align at top or

bottom, they may not have been tight

against the stops. |

|

|

|

|

|

|